ASSYST CAD System

If you're working in the ready-to-wear, fashion, or technical textile industries, drawing and designing patterns has become second nature. But admittedly, these processes have taken a lot of time and effort over the years. It's at this point that a solution quietly emerges: ASSYST CAD System.

What this system offers can't be explained in just a few short paragraphs. Let's explore it together.

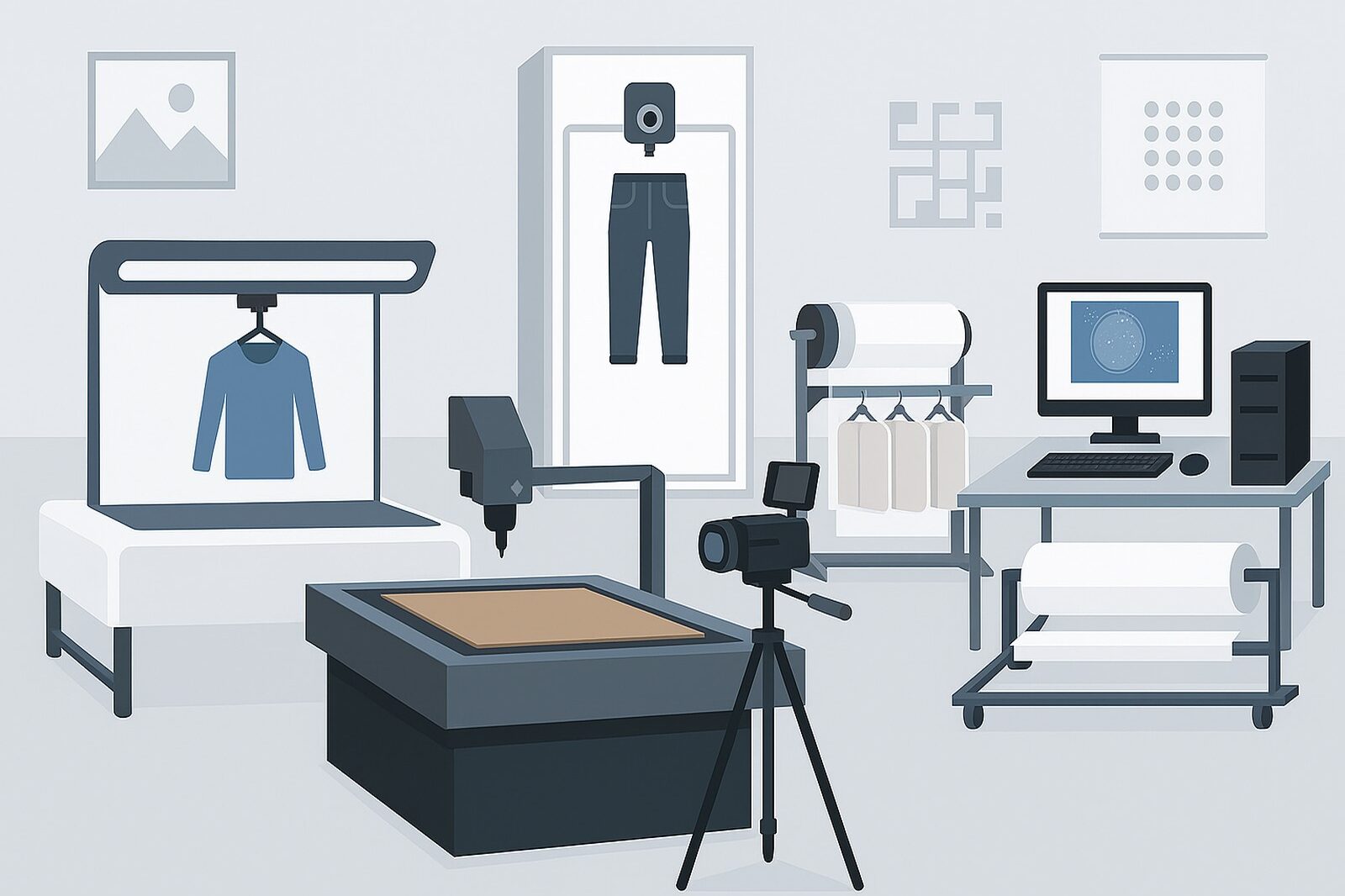

Patterns are now prepared digitally

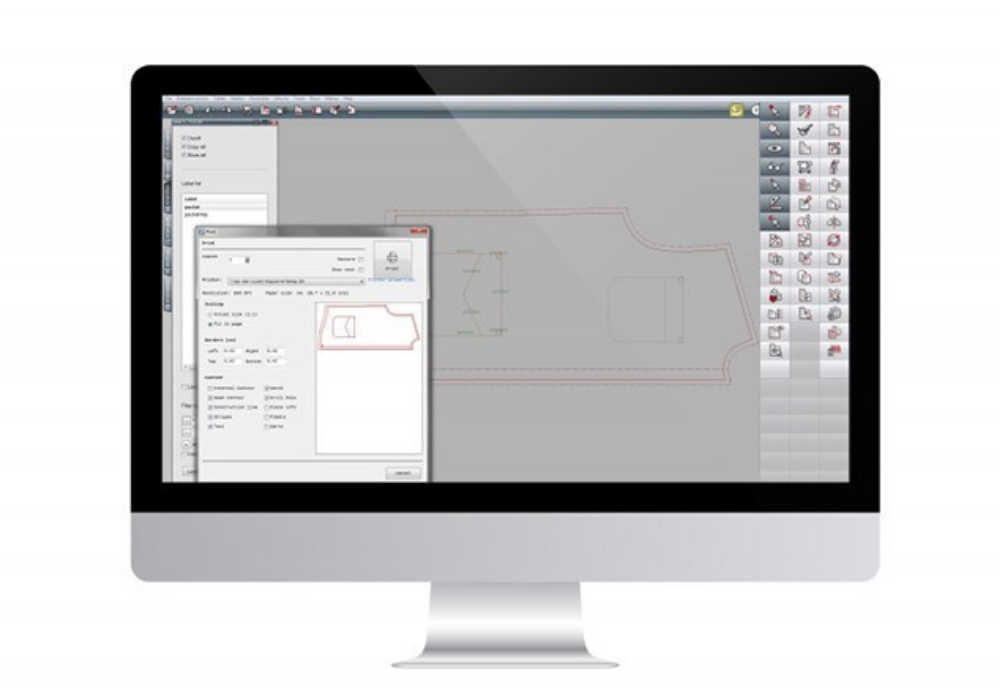

In the past, patterns were drawn by hand, measured repeatedly, and often remade. Now, a digital table, smart software, and a few clicks open up a whole new world. ASSYST brings pattern making to the computer, making the process much faster and more accurate. Precise digital tools are replacing hand drawing.

In this way, hours spent at the drawing table are now being replaced by much more controlled, much more flexible work in front of the screen.

Automation Makes Everything Easier

Constantly repetitive tasks can be quite tiring at times. But this is where ASSYST comes in. Thanks to the system's intelligent automation tools, operations like sizing and pattern duplication can be completed in a single move.

Tasks that once required countless hours can now be completed in a matter of seconds. This saves time and allows users to focus their energy on more creative endeavors.

The result can be seen before the sample planting is completed.

Being able to see how a garment will look before it's even sewn sounds like magic, right? But now it's possible. Thanks to ASSYST's 3D simulation feature, prepared patterns are brought to life on a digital mannequin.

It's easy to tell from the outset how the fabric will look on the garment, where it will sit, or where it will bunch up. This shortens the sampling process and prevents waste.

Fabric Usage Is Now Smarter

Fabric is perhaps one of the most valuable raw materials. And using it correctly directly impacts costs. This is where cutting planning comes into play. Thanks to cutting charts created with ASSYST, fabric can be used in the most efficient way.

Unnecessary waste is eliminated, allowing more products to be produced with less fabric. This not only provides an economical but also an environmentally friendly approach.

Uninterrupted Flow from Design to Production

Design and production processes are often disconnected. A design change goes unnoticed until it's implemented in production. However, with ASSYST, this disconnect is eliminated. Every design change is integrated into the production system.

This way, work progresses faster and errors are minimized. The entire team works on the same system, so no one has to fall behind.

A Smart Infrastructure Suitable for the Fashion Industry

ASSYST isn't just any software. It's a system developed with the needs of the fashion and textile industries in mind. Fabric information, pattern variations, size conversions—everything you need is gathered in one place.

Whether you're a small workshop or a large production facility, it can be adapted to any workplace. Moreover, thanks to its modular structure, you can customize the system by using only the features you need.

Easy to Use, Quick to Learn

Technology often seems complex. But that's one of the things we love most about ASSYST: it's incredibly easy to use. With its simple interface and clear menus, even first-time users can quickly adapt.

There's no need to spend weeks learning the system. In fact, once you get the hang of it, it's hard to even want to go back to the old ways.

Your Information is Safe, Your Business is Uninterrupted

ASSYST isn't just a design tool; it also protects your data. Your information is backed up in the system. Thanks to its cloud-based architecture, you can access it from anywhere.

You can continue your work where you left off, even in a different city or country, without having to be in the office. This provides both flexibility and ensures business continuity.

So What's Next?

With all these features, the ASSYST CAD System is not just a software program; it's also a companion that transforms the perspective on the production process. It opens a whole new door to faster, more efficient, and more sustainable production.

Now you might be wondering: How ready is your production line for this transformation?