MERSMANN TABLE SYSTEMS CTS

When you step into a production area, you realize how orderly the seemingly complex machines actually operate. Everything has a rhythm, like a well-orchestrated symphony. To achieve this order, certain systems must perform their functions flawlessly. This is precisely where MERSMANN TABLE SYSTEMS CTS comes into play.

What is the CTS System and How Does It Work?

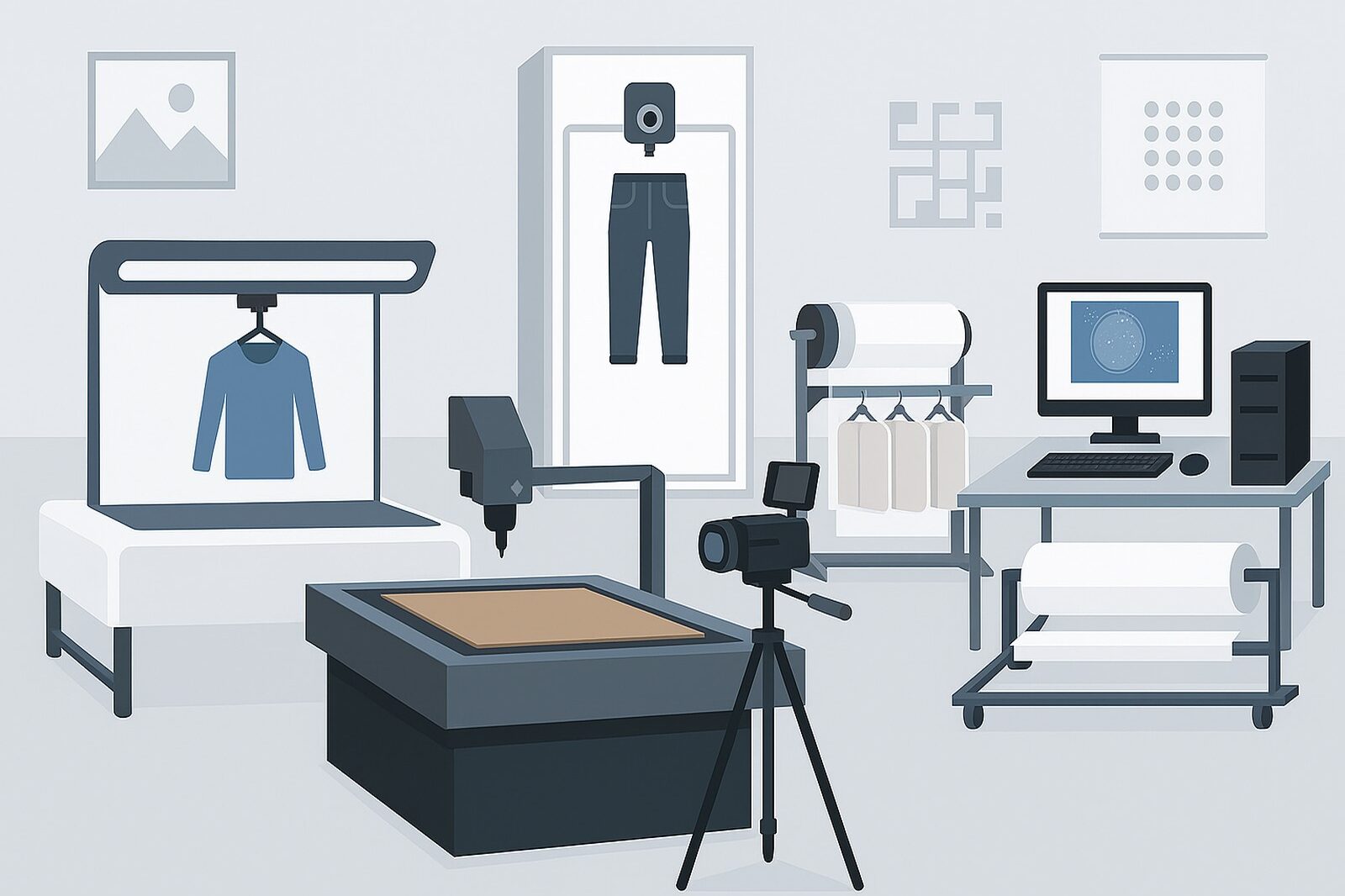

When you think of the CTS system, you might not immediately grasp what it entails. However, when you consider how fabrics are spread evenly, tautly, and economically on a production line, you realize the key role this system plays. CTS stands for "Controlled Tension Spreading." This technology, which ensures both even and measured spreading of fabrics, has become a fundamental cornerstone of production.

So how does this system work? It's actually operated without much effort from the user. Thanks to the automated mechanism, sensitive sensors detect the fabric tension, and the system constantly adjusts itself based on this data. While the user simply monitors the process, the machines meticulously perform their work.

Saving Time and Material in Fabric Laying

We know how precious time is in production processes. Similarly, every meter of fabric is precious. One of the greatest advantages of the CTS system is the significant gains achieved in both of these aspects. Fabrics are laid faster, while waste due to unnecessary tension or curling is minimized.

Over time, measurements have shown that laying can be done up to 30% faster than traditional methods. It's important to note that this increased speed also positively impacts other stages of production. Some companies have even observed reduced shifts, resulting in less fatigue for workers.

Automatic Tensioning and Uniform Spreading Technology

Maintaining both uniformity and the desired tension in fabric during the spreading process has been a problem for many years. It has been frequently stated that manual adjustments are often insufficient, and that deformations occur, especially in long-length fabrics. CTS offers a radical solution to these problems.

The automatic tensioning system prevents any rippling or puckering on the fabric's surface. This significantly reduces the margin of error once the cutting process begins. Because each layer is laid with the same care, every final product achieves the same standard of quality.

Working Mechanism Compatible with All Types of Fabric

It's well known that fabric types exhibit different properties. While cotton fabric behaves differently, lycra requires much more precise stretching. Therefore, it was thought that a single system wouldn't be enough to treat all fabrics. However, the CTS system eliminates this difficulty.

The smart control panel allows fabric type selection, and the system adjusts itself accordingly. The user simply selects the fabric type; the rest is handled by automation. This ensures that all fabrics, whether flexible, stiff, slippery, or thick, are processed with the same care.

Increased Efficiency in the Production Process

A system's amortization is measured by how quickly it pays for itself. Even within the first few months of installing the CTS system, noticeable increases in production efficiency were observed. This shortened the return on investment period.

Operation times have been shortened, error rates have been reduced, and personnel intervention has been reduced. This has allowed for a more controlled and standardized production flow. In the long run, both production capacity and customer satisfaction have been increased.

Compact Design, Maximum Functionality

Space saving is another key consideration in production areas. The CTS system's compact design allows for integration without taking up significant space. This simplifies use even in production facilities with limited space.

Designed without compromising functionality, this system saves both space and energy. Furthermore, its mobile carrying device allows for easy transport to different lines.

Durability and Stability in Industrial Use

The durability of the machinery used in a production line is a decisive factor in system sustainability. The CTS is designed to prevent performance degradation even during extended periods of use. Its robust chassis structure resists industrial-level vibration and loads.

Additionally, the materials used on its exterior allow for easy cleaning and prevent dust accumulation. This extends maintenance intervals and minimizes the risk of malfunction. This has been seen as a significant advantage for the user, both in terms of cost and labor.

Ease of Installation and Integration

While it might seem challenging to implement a new system, CTS has also provided a user-friendly experience. Installation was completed in just a few hours and can be easily integrated into existing production lines.

In fact, some companies have even been able to make the transition without halting production lines. This system, which integrates with ERP and production management systems thanks to its software infrastructure, has also supported the transition to digitalization.