MERSMANN TABLE SYSTEMS HVM

-

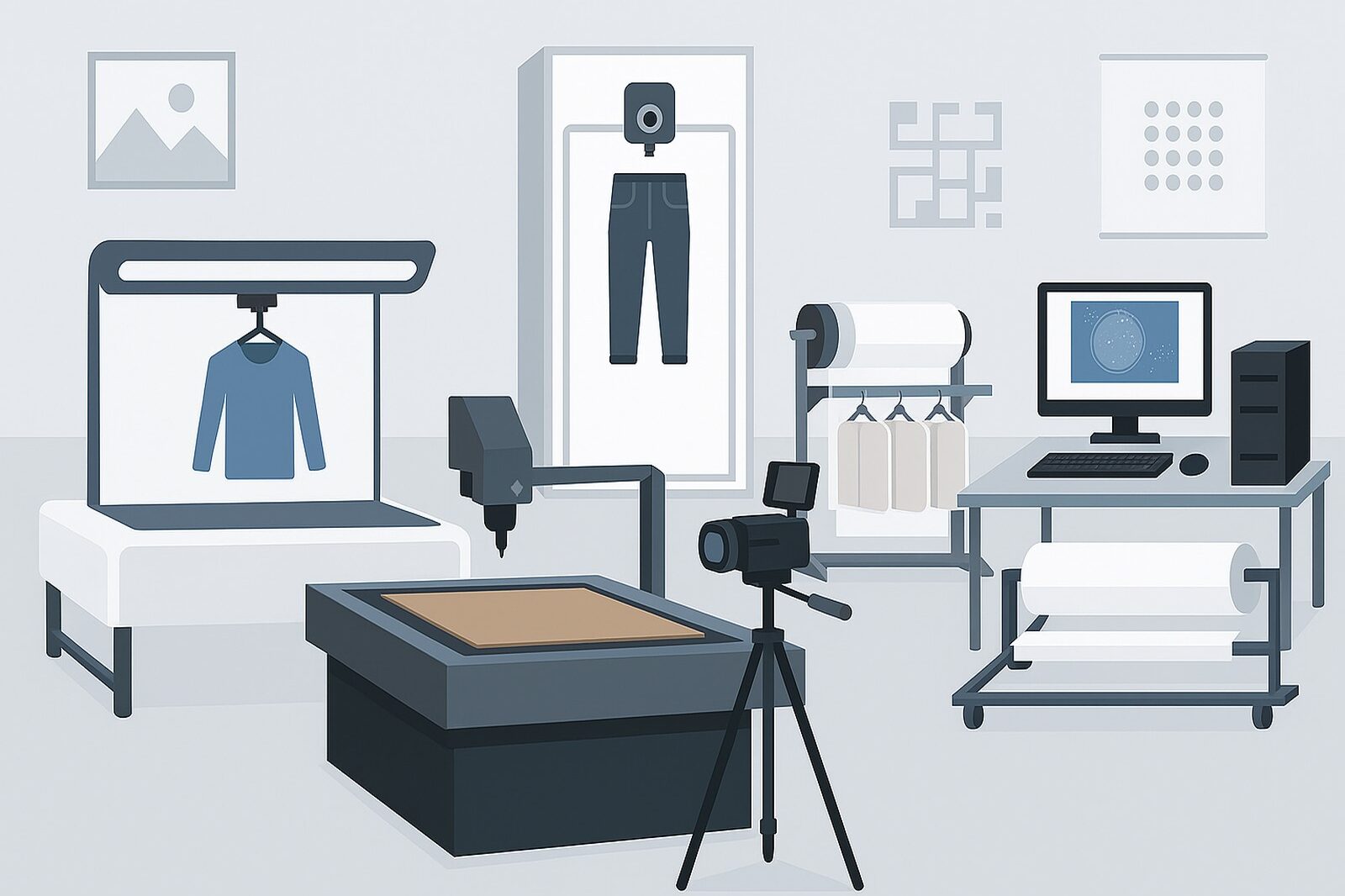

Introduction of the High Efficiency Paving (HVM) System

While it's well known that every step in production impacts the larger picture, it's quite concerning that spreading systems have been overlooked for so long. When fabrics are folded using traditional methods, the costs of unnoticed errors accumulate over the years, leading to situations that are difficult to repair.

This is precisely where HVM systems, developed by MERSMANN, came into play. Equipped with HVM (High Volume Marker) technology, these table systems are positioned not only as automated spreading tools but also as production intelligence.

With this system, fabric is no longer simply laid; the production process is also streamlined. This structure minimizes human intervention, making the laying process error-free, fast, and sustainable.

But the truly striking aspect of the system doesn't end there. Was a world where fabric wasn't wasted, energy was used effectively, and waste rates were minimized possible? The answer to this question will become clearer in the next section.

-

Smart Spreading Solutions That Reduce Fabric Consumption

Fabric, as the most basic raw material in production, represents a significant cost. Therefore, how efficiently each meter is used directly impacts profitability. It's a curious question how fabric consumption is controlled with the HVM system.

Thanks to smart sensors and software integrated into the system, the fabric is prevented from unwinding excessively during the spreading process. This translates to savings of hundreds of meters of fabric per month, especially in mass production.

What's more, automatic alignment and tension control ensures each layer is laid down evenly over the previous one, resulting in fewer errors, less waste, and cleaner results when it comes to cutting.

This entire optimization process not only provides businesses with cost advantages but also contributes greatly to environmental sustainability.

But has anyone ever considered how this system provides internal automation and successfully manages folding and leveling processes? The next section will reveal this clever mechanism.

-

Automatic Folding and Leveling Feature

In traditional systems, the biggest time loss was due to fabric misalignment or fluctuations during the folding process. With the HVM system, this problem has been completely eliminated.

Thanks to the system's built-in automatic leveling motors and folding sensors, the fabric finds its own levelness with each pass. The user simply initiates the process, and the entire process is then managed automatically.

This automation not only saves time but also significantly reduces operator errors. This translates to less rework, more production time, and happier customers.

But the impressive aspects of this system don't end there... How can this automated structure adapt as product diversity increases? To what extent is the system's success sustained across different fabric types?

These questions will be discussed in detail in the next section…

-

Advantages in Fast Transitions and Product Diversity

One of the biggest challenges in textile production is the time consuming transition from one model to another. However, with HVM systems, these transitions are no longer a problem.

It has been observed that the system can automatically adjust settings for different fabric types, thicknesses, and pattern structures. The tension force and folding style are automatically adjusted based on the fabric type selected by the operator, significantly reducing changeover time.

This offers a significant competitive advantage, especially for companies operating with high levels of diversity. Furthermore, the reduction in changeover times has also led to increased production capacity.

However, how is the accuracy of the work done throughout these processes ensured? How are faulty cuts prevented? Now comes another point of interest...

-

Preventing Faulty Cuts with HVM Systems

Incorrect cutting not only wastes fabric but also harms many critical factors, such as labor, time, and customer satisfaction. Therefore, HVM systems were developed with this in mind.

Advanced measurement sensors ensure precise alignment across every layer of fabric, highlight cutting lines, and prevent deviations through in-system checks. This automated quality control eliminates the risk of surprises at the end of production.

Additionally, the system's automatic shutdown and operator warning features in the event of an error make the entire process safer. This provides significant security for both the operator and the business.

But what made the system so smart? Its modular architecture and integration capabilities, of course. So, how was this modular structure achieved?

-

Modular Structure Compatible with Your Production Line

Not every production line is the same. Different sizes, different flows, different goals... Mersmann acted with this awareness and developed the HVM system with a modular structure.

This system allows each business to create custom solutions tailored to their specific production processes. Table lengths, spreading area widths, heights, and control panel layouts can be customized to meet the specific needs of the business.

Thanks to the modular structure, the system is easier to integrate into the existing production line and is also made ready for future growth.

But the system's adaptability doesn't end there... Because HVM integrates with production not only physically but also digitally.

And now, the next topic will cover how this digital intelligence is reflected in production…

-

Digital Tracking Opportunity Offered by Mersmann Technology

We are now in the age of data-driven production. HVM systems are not only keeping pace with this transformation, they are also leading it.

Production data collected through the system can be monitored, analyzed, and reported via cloud-based platforms. This allows for measuring the performance of paving processes, identifying bottlenecks, and easily identifying optimization opportunities.

Additionally, the system's integration with mobile devices allows managers to monitor production anytime, anywhere. This should be considered a major step in transparency and control.

But for this technology to achieve long-term success, something else is needed: durability. But how durable is this system?

-

Long-Life System Architecture

When making a manufacturing investment, it's important to consider not only the present but also the future. HVM systems envision this future, and every component of the structure is designed with durability in mind.

Stainless steel surfaces, impact-resistant side bodies, long-lasting engine and drivetrain… All these details ensure that the system will operate with the same performance as the first day for many years.

Furthermore, minimizing the need for periodic maintenance reduces the total cost of ownership, resulting in significant savings not only in the short term but also in the long term.